- The publication, authored by Juan Esteban Arjona Rodríguez from the LKR team, is grounded in findings aimed at advancing direct liquid hydrogen refuelling technologies.

A new master’s thesis published within the European project ALRIGH2T is shedding light on the thermo-structural behavior of cryogenic hydrogen tanks, a key challenge for the future of zero-emission aviation. The thesis, entitled “Thermo-Structural Behaviour of Cryogenic Tanks During Cooldown: A Comparison Between Analytical and Numerical Methods”, was authored by MSc. Juan Esteban Arjona Rodríguez, Junior Research Engineer at LKR and was formally presented in August 2025.

Towards reliable predictions: analytical models in tank cooldown

The research was conducted under Work Package 4: “Direct Refuelling Technology”, led by SAG Group, whose main goal is to develop technologies for the direct refuelling of aircraft with liquid hydrogen (LH2). Within this framework, Arjona Rodríguez’s thesis focused specifically on evaluating the capability of analytical models to predict spatial variation and peak stress values that arise during the cooldown of cryogenic tanks, thereby supporting their use in preliminary design phases.

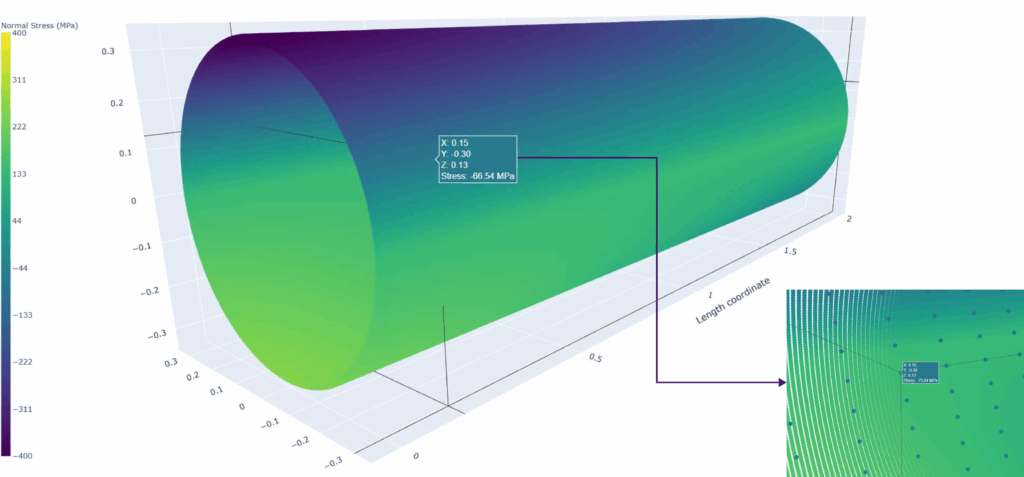

To this end, the study examined the structural response of a horizontal 316L stainless steel cylinder with torispherical heads, modelled after the demonstrator developed in ALRIGH2T. The tank was simplified as a thin cylindrical shell to capture the effects of internal pressure, and as a Euler–Bernoulli beam to represent gravity and vertically stratified thermal loads. Additionally, circumferential thermal stresses were assessed using two-dimensional thermoelasticity. The overall response was then determined through superposition, under the assumptions of linear elasticity and temperature-independent material properties.

As Arjona Rodríguez highlights:

“One of the key challenges is the design of cryogenic liquid-hydrogen tanks. These tanks face extreme conditions — very low temperatures, steep thermal gradients, and high internal pressure — especially during ground cooldown and refuelling. Understanding how they deform and where stresses build up is critical for both safety and efficiency”.

Methodology and validation

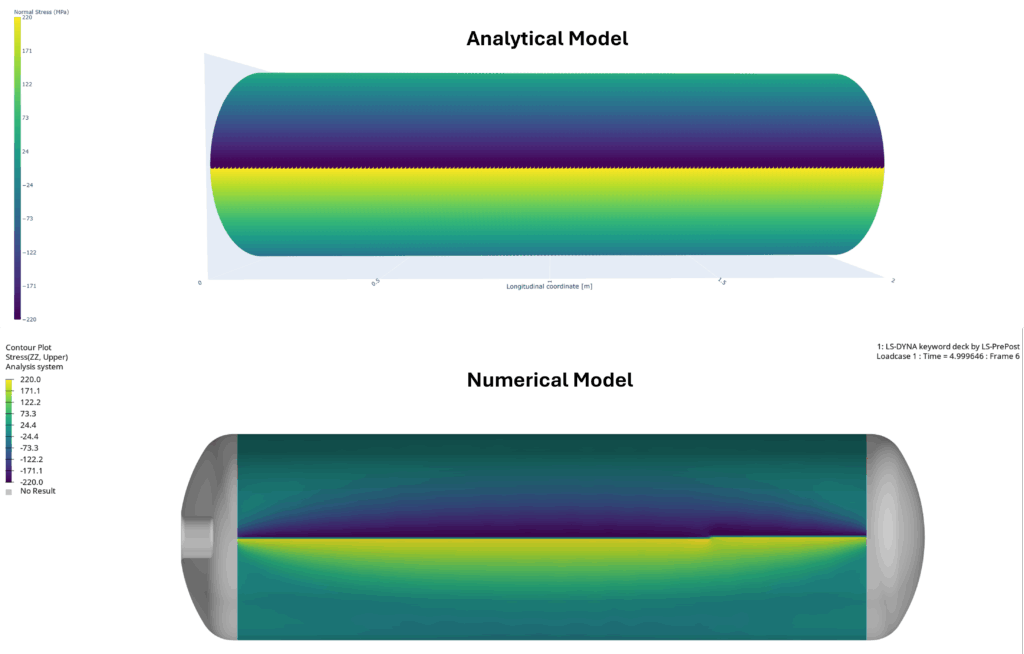

In order to validate the analytical approach, the resulting model was benchmarked against detailed LS-DYNA finite element simulations. These simulations incorporated internal pressure, idealised liquid-nitrogen thermal gradients, and self-weight, allowing for a direct comparison between simplified models and advanced computational techniques. This process provided a robust assessment of both the accuracy and the practical applicability of analytical methods for preliminary tank design.

Reflecting on his contribution, Arjona Rodríguez explained:

“As part of my master’s thesis, I worked on predicting these thermo-mechanical stresses using simplified analytical models based in beam and shell theory. These models were then benchmarked against detailed finite element simulations to assess their accuracy and applicability.

Von Mises Stress contour plots: Comparison between analytical and numerical model.

Research outcomes

The thesis produced promising findings, demonstrating that simplified analytical models can serve as reliable tools for predicting stress distributions in cryogenic tanks at the design stage. According to the author:

“Despite their reduced complexity, these models produced stress predictions that were consistent with detailed finite element analyses, but with significantly lower computational cost and faster turnaround”.

Consequently, such models prove especially valuable during the early phases of design, when rapid evaluation and iteration are crucial. While they cannot fully replace advanced simulations and experimental validation, analytical approaches provide engineers with powerful preliminary insights, inform design decisions, and help pinpoint critical areas where more detailed studies are required.

All the findings are fully aligned with the objectives of the ALRIGH2T project and have contributed to a deeper understanding of the accuracy and applicability of simplified analytical models for predicting the thermo-structural response of a cryogenic pressure vessel during the cooldown phase.

Analytical model results visualized in Python based 3d-interactive contour plot.

About the author

Juan Esteban Arjona Rodríguez, Mechanical Engineer, is passionate about research in the field of mechanics of materials. He has experience in structural simulation using Finite Element Analysis (FEA), computer-aided design and manufacturing (CAD/CAM software) and additive manufacturing. He currently works at LKR Leichtmetallkompetenzzentrum Ranshofen GmbH, a subsidiary of the Austrian Institute of Technology (AIT). Within the framework of the ALRIGH2T project, LKR contributes through its Competence Unit “Light Metals Technologies”, which focuses on high-quality light metal alloys, sustainable manufacturing processes, and functionally integrated lightweight components.